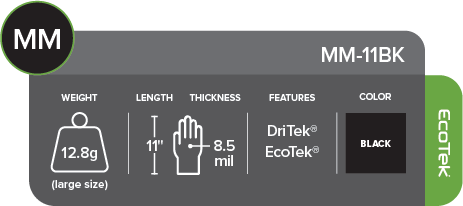

MM-11BK

MM-11BK

Sustainable Nitrile Exam Gloves with DriTek® and EcoTek®

-

Chemotherapy Tested

Chemotherapy Tested -

Fentanyl & Gastric Acid Tested

Fentanyl & Gastric Acid Tested -

SHA Approved

SHA Approved -

British Safety Industrial Federation

British Safety Industrial Federation -

UL Classified

UL Classified -

Instruction for Use

Instruction for Use -

EN Food Safe

EN Food Safe -

ANSI Abrasion 3

ANSI Abrasion 3 -

ISO 374-1:2016 Type B JKT

ISO 374-1:2016 Type B JKT -

EN374-5:2016 VIRUS

EN374-5:2016 VIRUS -

EN388:2016 - 3000X

EN388:2016 - 3000X -

CE 0493

CE 0493

- Multilayer: lasts 3x longer, ANSI and EN Level 3 abrasion resistance

- DriTek absorbent lining keeps hands dry and cool

- Fully textured surface delivers excellent grip

- Beaded cuff allows easy donning and doffing

- 100% air inspected / consistent thickness tip to cuff

Description

We’ve combined sweat management and unprecedented strength in a fully-textured glove that delivers the ultimate in comfort and performance.

Additional features include an extended-cuff for splash protection and ANSI/EN level 3 abrasion resistance for a glove that lasts three times longer than standard nitrile gloves. ASTM tested against viral penetration.

Standards – Compliance

EN ISO 21420:2020

EN 455-2000-2015

ASTM D6319-19

ASTM D6978-05 (2019)

ASTM F1671-13

ASTM F739-12

Reach EU 1907/2006

EU 2016/425

ANSI/ISEA 105-2016

CAT III Complex Design

FDA 21 CFR 177.2600

Features and Benefits

- DriTek® Comfort Technology with absorbent lining that wicks away moisture for added extended use

- EcoTek® Sustainable Technology without any performance loss

- ANSI/EN Level 3 abrasion resistance for durability and extended wear

- Fully textured surface for excellent grip

- Optimal thickness for durability and tactile sensitivity

- 1.5 AQL exceeds laboratory standards

- Up to 3x longer lasting than standard nitrile gloves

- SHA Dermatologically Approved

Typical Applications

For Medical Use

Chemical Handling

First Responder EMS

Product Technologies

EcoTek

Yes

DriTek

Yes

Specifications

Glove Type

Single-Use

Abrasion Level

ANSI 3

Fit Type

Ambidextrous

Grade

Powder-Free Exam

Material

Nitrile

Finger Thickness mil

10.1mil

Finger Thickness mm

0.26mm

Palm Thickness mil

8.5mil

Palm Thickness mm

0.22mm

Cuff Thickness mil

7.0mil

Cuff Thickness mm

0.18mm

Color Outer

Black

Surface Outer

Fully Textured

Surface Inner

DriTek

Length inch

11.0"

Length mm

280mm

Palm Width inch

4.3"

Palm Width mm

109mm

Weight in Grams

12.8g

Cuff Type

Beaded

AQL

1.5

Country Origin

China

Performance

Tensile Before

17 MPa

Tensile After

16 MPa

Elongation Before

560%

Elongation After

520%

| Size | Item Number | UPC Number | Packaging Unit |

|---|---|---|---|

| XS (5 ½ - 6) | N260881 | 0130616489228814 | 50/Bx 500/Cs |

| S (6 ½ - 7) | N260882 | 0130616489228821 | 50/Bx 500/Cs |

| M (7 ½ - 8) | N260883 | 0130616489228838 | 50/Bx 500/Cs |

| L (8 ½ - 9) | N260884 | 0130616489228845 | 50/Bx 500/Cs |

| XL (9 ½ - 10) | N260885 | 0130616489228852 | 50/Bx 500/Cs |

| 2XL (10 ½ - 11) | N260886 | 0130616489228869 | 50/Bx 500/Cs |

| 3XL (11 ½ - 12) | N260887 | 0130616489228876 | 50/Bx 500/Cs |

Vend Pack

| Size | Item Number | UPC Number | Packaging Unit |

|---|---|---|---|

| S (6 ½ - 7) | N164882 | 0616489168829 | 8/Pk 640/Cs |

| M (7 ½ - 8) | N164883 | 0616489168836 | 8/Pk 640/Cs |

| L (8 ½ - 9) | N164884 | 0616489168843 | 8/Pk 640/Cs |

| XL (9 ½ - 10) | N164885 | 0616489168850 | 8/Pk 640/Cs |

| 2XL (10 ½ - 11) | N164886 | 0616489168867 | 8/Pk 640/Cs |

| 3XL (11 ½ - 12) | N164887 | 0616489168874 | 8/Pk 640/Cs |

ANSI-ISEA-105 Chemical Permeation Breakthrough Times

| Chemical | CAS No. | Breakthrough Time (BTT) Average (Minutes) ASTM F739-12 | ANSI-ISEA 105 Level | Report No. |

|---|---|---|---|---|

| Acetic Acid (Glacial) | 64-19-7 | 15 | 1 | |

| Citric Acid (50%) | 77-92-9 | >240 | 5 | |

| Hydrochloric Acid (37%) | 7647-01-0 | 8 | 0 | |

| Hydrochloric Acid (20%) | 7647-01-0 | >240 | 5 | |

| Perchloric Acid (70%) | 7601-90-3 | >60 | 3 | |

| Nitric Acid (70%) | 7697-37-2 | 15 | 1 | |

| Sulfuric Acid (96%) | 7664-93-9 | 13 | 1 | |

| Sulfuric Acid (50%) | 7664-93-9 | >240 | 5 | |

| Phosphoric acid (85%) | 7664-38-2 | >240 | 5 | |

| Hydrogen Peroxide (30%) | 7722-84-1 | >30 | 2 | |

| Ammonium Hydroxide (25%) 1 | 1336-21-6 | 93 | 3 | |

| Sodium Hydroxide (40%) | 1310-73-2 | >240 | 5 | |

| Sodium Hypochlorite | 7681-52-9 | >240 | 5 | |

| Ethidim Bromide (5%) | 1239-45-8 | >240 | 5 | |

| Chloroform | 67-66-3 | <5 | 0 | |

| DMSO | 67-68-5 | <5 | 0 | |

| DMSO (10%) | 67-68-5 | >30 | 2 | |

| Heptane | 142-82-5 | 65 | 3 | |

| Hexane | 110-54-3 | 21 | 1 | |

| Petroleum ether | 8032-32-4 | 39 | 2 | |

| Stoddard Solvent | 8052-41-3 | 25 | 1 | |

| Phenol (0.5%) | 108-95-2 | >60 | 3 | |

| Xylene | 1330-20-7 | <5 | 0 | |

| Acetone | 67-64-1 | <5 | 0 | |

| Acetonitrile | 75-05-8 | <5 | 0 | |

| Formalin / Formaldehyde 37% | 50-00-0 | >240 | 5 | |

| 2-butoxyethanol | 111-76-2 | 37 | 2 | |

| Diacetone alcohol | 123-42-2 | 11 | 1 | |

| Ethyl alcohol / Ethanol (99%) | 64-17-5 | 11 | 0 | |

| Ethyl alcohol / Ethanol (70%) | 64-68-5 | >30 | 2 | |

| Isopropanol / IPA (99%) | 67-63-0 | 63 | 3 | |

| Methanol | 67-56-1 | <5 | 0 |

The data provided is based on gloves tested by an accredited laboratory under conditions in accordance with ASTM F739-12 and reported according to the ANSI-ISEA 105 standard. Data is provided for guidance only and actual user results may vary due to conditions. User should always assess in advance the suitabiliity of gloves for use in specific applications. For more information, call us at +1.510.429.8692 or visit swsafety.com.

EN374-3 Chemical Permeation Breakthrough Times

| Chemical | CAS No. | Breakthrough Time (BTT) Average (Minutes) ASTM F739-12 | EN374-3 Level | Report No. |

|---|---|---|---|---|

| Acetic Acid (Glacial) | 64-19-7 | 15 | 1 | |

| Citric Acid (50%) | 77-92-9 | >240 | 5 | |

| Hydrochloric Acid (37%) | 7647-01-0 | 8 | 0 | |

| Hydrochloric Acid (20%) | 7647-01-0 | >240 | 5 | |

| Perchloric Acid (70%) | 7601-90-3 | >60 | 3 | |

| Nitric Acid (70%) | 7697-37-2 | 15 | 1 | |

| Sulfuric Acid (96%) | 7664-93-9 | 13 | 1 | |

| Sulfuric Acid (50%) | 7664-93-9 | >240 | 5 | |

| Phosphoric acid (85%) | 7664-38-2 | >240 | 5 | |

| Hydrogen Peroxide (30%) | 7722-84-1 | >60 | 3 | |

| Ammonium Hydroxide (25%) 1 | 1336-21-6 | 115 | 3 | |

| Sodium Hydroxide (40%) | 1310-73-2 | >240 | 5 | |

| Sodium Hypochlorite | 7681-52-9 | >240 | 5 | |

| Ethidim Bromide (5%) | 1239-45-8 | >240 | 5 | |

| Chloroform | 67-66-3 | <5 | 0 | |

| DMSO | 67-68-5 | <5 | 0 | |

| DMSO (10%) | 67-68-5 | >30 | 2 | |

| Heptane | 142-82-5 | 65 | 3 | |

| Hexane | 110-54-3 | 31 | 1 | |

| Petroleum ether | 8032-32-4 | 39 | 2 | |

| Stoddard Solvent | 8052-41-3 | 25 | 1 | |

| Phenol (0.5%) | 108-95-2 | >60 | 3 | |

| Xylene | 1330-20-7 | <5 | 0 | |

| Acetone | 67-64-1 | <5 | 0 | |

| Acetonitrile | 75-05-8 | <5 | 0 | |

| Formalin / Formaldehyde 37% | 50-00-0 | >240 | 5 | |

| 2-butoxyethanol | 111-76-2 | 37 | 2 | |

| Diacetone alcohol | 123-42-2 | 12 | 1 | |

| Ethyl alcohol / Ethanol (99%) | 64-17-5 | 11 | 1 | |

| Ethyl alcohol / Ethanol (70%) | 64-68-5 | >30 | 2 | |

| Isopropanol / IPA (99%) | 67-63-0 | 63 | 3 | |

| Methanol | 67-56-1 | <5 | 0 |

The data provided is based on gloves tested by an accredited laboratory under conditions in accordance with ASTM F739-12 and reported according to the EN374-3 standard. Data is provided for guidance only and actual user results may vary due to conditions. User should always assess in advance the suitabiliity of gloves for use in specific applications. For more information, call us at +1.510.429.8692 or visit swsafety.com.

Product Technologies

Moisture-wicking flock-lined system for drier, cooler, more comfortable hands. Naturally manages sweat for healthier hands and easy donning and doffing. |

Sustainable nitrile technology without performance loss. |

|

PHOTOS |

Coming soon!

Coming soon!