Glove Intelligent Assistant

01.30.2024

The Ask GIA Blog has routinely discussed the imperatives of hand safety in the automotive industry across our weekly blogs. Previously, we have stated that gloves are hugely important as PPE (Personal Protective Equipment) in the automotive industry and can determine the outcome of hand safety in hazardous environments. In serious cases, not using proper PPE can result in the accidents that affect future hand mobility. The Occupational Health and Safety Administration (OSHA) and the Bureau of Labor Statistics (BLS) report that 70% of workers who experienced a hand injury were not wearing gloves.

Furthermore, the US Department of Labor reports that 23% of all workplaces related injuries involve injuries of the hand and fingers. The BLS details that an estimated 1 million workers need emergency medical care due to a severe hand injury every year. Workers who operate heavy machinery, including bulldozers and dump trucks and manufacturing workers who operate drill presses, lathes, and other large machinery are the most at risk for hand related injuries in the workplace. Therefore, it is imperative that workers in the automotive industry can access gloves that are fit for the job and comfortable to wear in the workplace. In fact, this week’s blog post will go over some of the advantages of SW products for workers in the automotive industry.

SW understands that automotive jobs often need workers to maintain high dexterity in various different and difficult working conditions. This is made even more difficult when the PPE used restricts free and flexible movement of the hand. The subtle annoyance causes workers to forgo hand protection rather than properly protecting their hands. With SW technology, our R&D team has engineered mechanical gloves that offer enhanced grip for handling wet and oily machinery. This ensures safety and dexterity when repairing or handling automotive parts. These gloves are ideal for intricate work with small parts, making them an essential asset in the automotive industry while also catering to the comfort of working long hours.

SW’s GraphEx series offers thick cut protection required for glass and sheet metal handling without compromising the flexibility, dexterity, and grip of the glove. The proprietary AxiFybr yarn used to manufacture the GraphEx series is engineered at the molecular level to be 45% stronger and 21% more cut-resistant without sacrificing fit or comfort. The difference among our GraphEx series comes down to cut protection levels and abrasion resistance levels.

Most gloves will have anti abrasion properties depending on the material. Abrasion simply means the potential of being scrapped or wearing away due to friction. Cut levels measure the cut resistance of a glove or the ability for a glove to withstand the weight or force on the glove material before it is cut through by a blade. This is incredibly important as the more cut resistance a glove has, the more protection it will provide, especially when working with machinery or sharp equipment. GraphEx G45100 offers cut resistance level A4 protection and ANSI level 5 abrasion protection. GraphEx G46200 offers cut resistance level A4 protection and ANSI level 6 abrasion protection. Lastly, there is our GraphEx G66200 glove which offers cut resistance level A6 protection and ANSI level 6 abrasion protection.

|

|

|

Our TotalForm glove combines a liner made of 95% bio-based materials and EcoTek sustainable nitrile coating to provide exceptional comfort. It’s designed to protect the environment and your hands, offering cut resistance level A1 protection and ANSI level 4 abrasion protection.

|

Our other sustainable series combines our EcoTek and DriTek technology, coming together in our MegaMan glove. MegaMan is a more durable and multi-layer nitrile flock-lined glove that lasts three times longer than a regular nitrile glove. MegaMan provides ANSI level 3 abrasion protection and is the Optimal thickness for durability and tactile sensitivity.

|

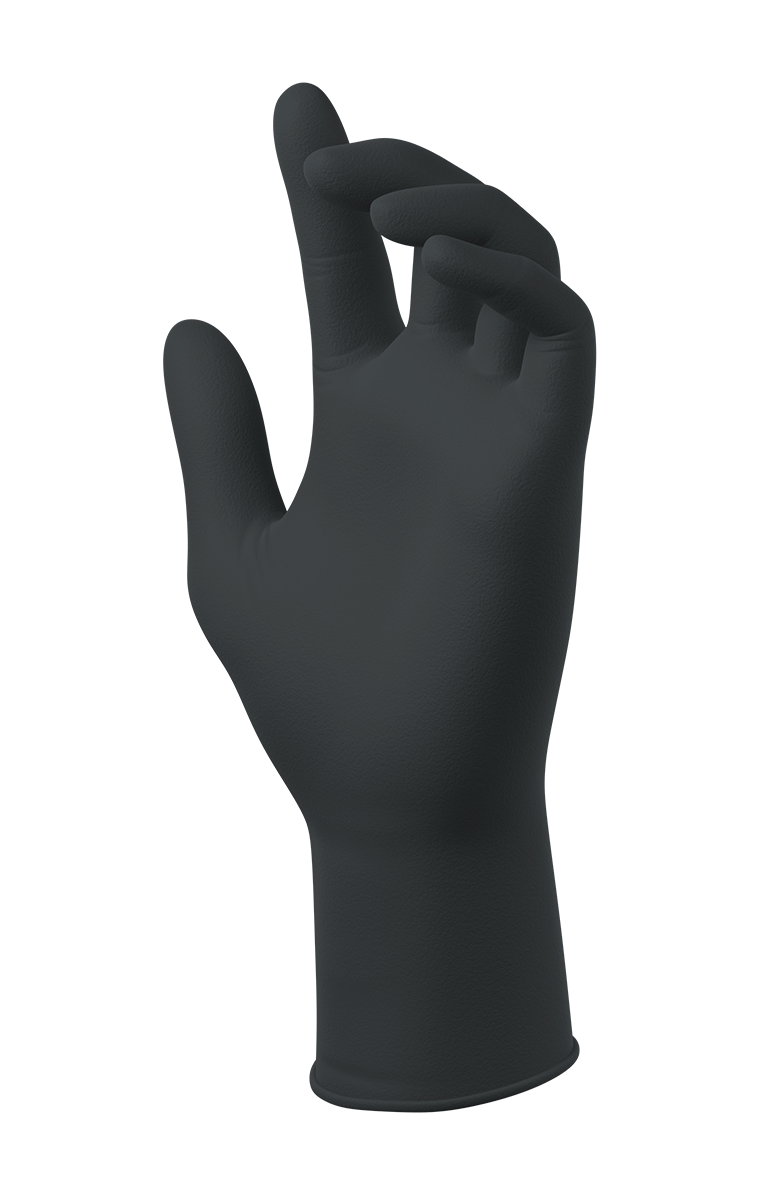

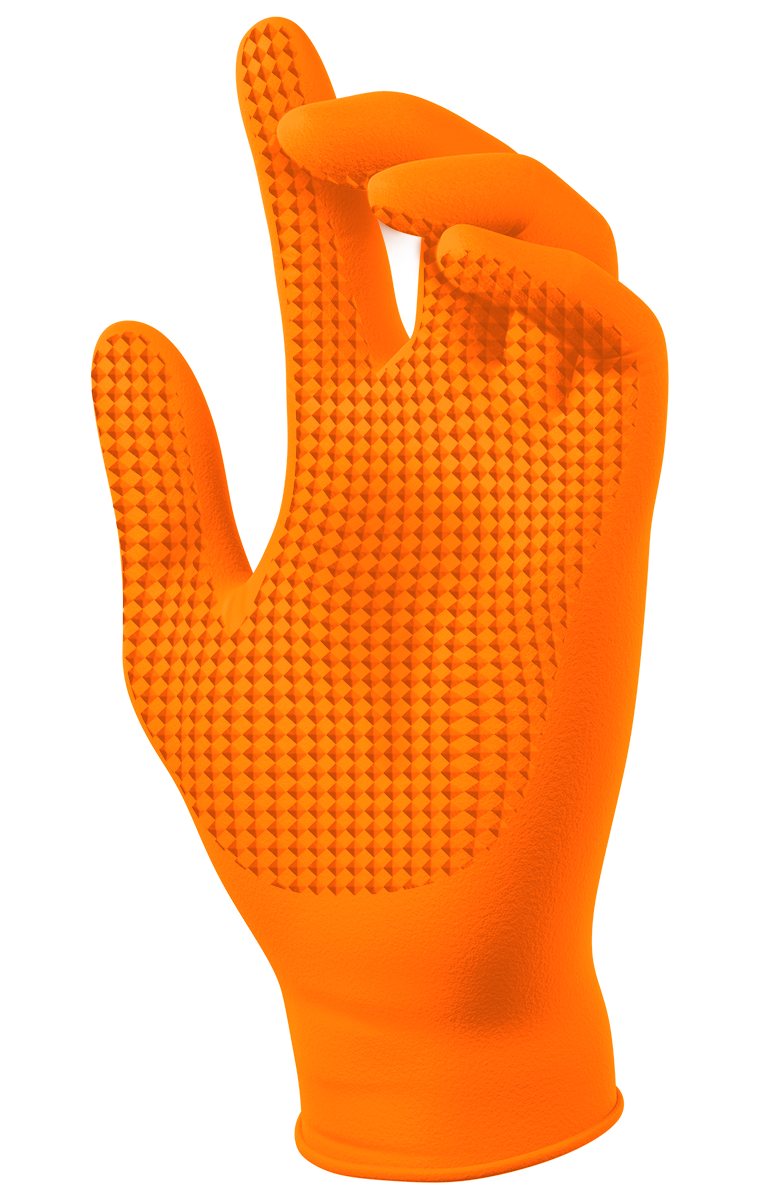

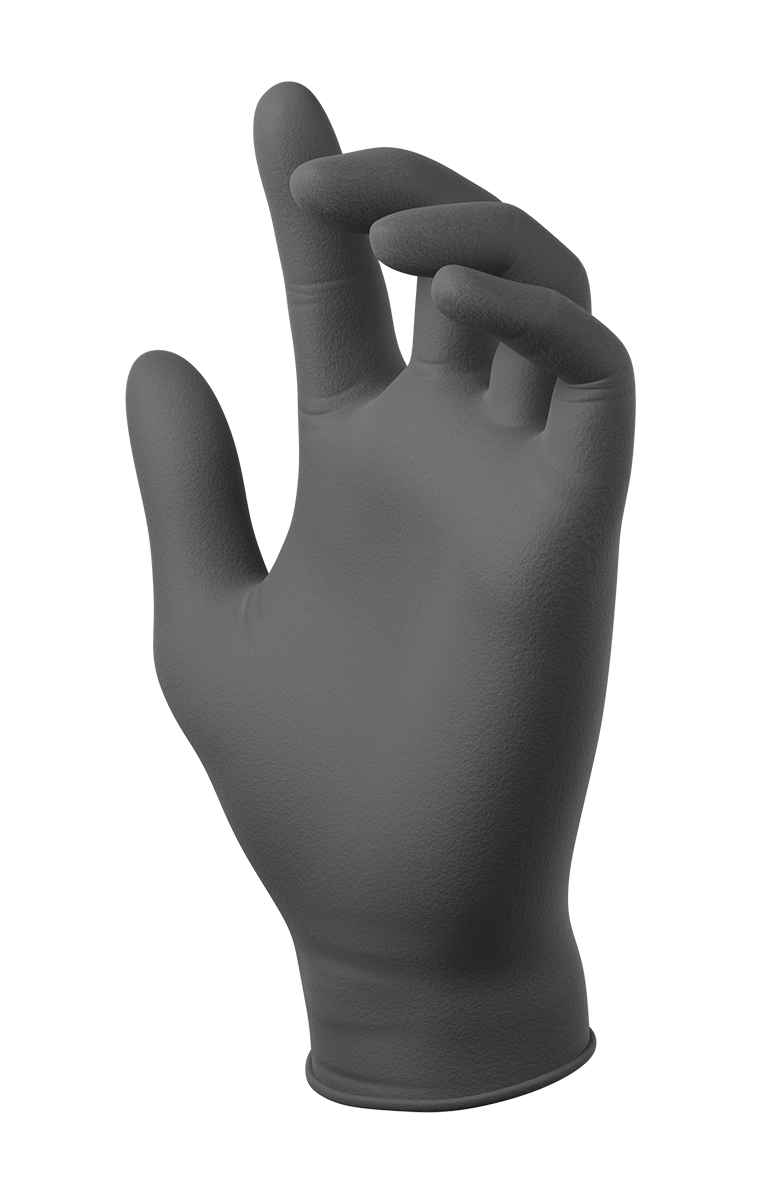

We also understand that workers in the automotive industry may not just need cut or abrasion protection but chemical protection too. SW’s PowerForm (PF-95OR, PF-95BK, and PF-95GY) glove series offers adequate chemical resistance required for most of the painting, adhesion, lubrication and cleaning tasks in automotive parts and components manufacturing. The glove series is tested against the American Society of Testing and Materials’ (ASTM) D6978 Standard Practice for Assessment of Resistance of Medical Gloves to Permeation by Chemotherapy Drugs. The tests have determined the gloves to be resistant up to 4 hours against permeable chemicals such as fentanyl and were also tested against simulated gastric acid.

|

|

|

Thus, they are suited for light chemical mixing, or other chemical handling and assembly. Our PF-95OR glove allows customers to work with confidence in rugged wet and oily environments. The orange TracTek nitrile gloves includes SW Performance Grip Technology which reduces the amount of strain placed on your hands and increases your motor control.

The Hi-vis orange color provides improved safety in the workplace. Our PF-95BK glove is a sustainable single-use glove that combines performance, durability, and tactile sensitivity. Lastly, our PF-95GY glove contains DriTek absorbent lining to keep hands dry and cool. It contains a fully textured surface to deliver excellent grip. All of our PowerForm series contain our EcoTek technology so our customers can make a conscious choice to prioritize sustainability and the best hand protection at the same time.

SW is dedicated to offering multiple levels of protection for our customers’ needs to make their protection more convenient!