The industrial worker faces a number of daunting challenges every day, and having the right tools is always critical for success. The most necessary tools, however, are their hands. In challenging environments, hands are the most susceptible to industrial related injury. In fact, the U.S. Bureau of Labor Statistics (2019) reported that of all industrial occupational injuries resulting in medical leave, hand injuries are the second most common. Among the upper extremity, which include the shoulder, arm, hand and wrist, hand injuries account for 45% of this category. There is a critical need in demanding industrial environments for proper mechanical hand protection to avoid injury and ensure worker productivity.

There are a variety of cut-resistant gloves on the market, and they are typically made with synthetic fibers – and these fibers tend to determine their level of cut resistance. While these gloves can offer higher levels of cut protection, they historically have done this at the expense of worker comfort, hand dexterity, and long-term durability. Many gloves for industrial workers are made with abrasive, lower quality materials, resulting in lower comfort and breathability, increased hand fatigue, and they typically lose their cut-resistant properties over time. When faced with the choice between comfort or proper cut protection, many industrial workers settle for an option that only meets one of these needs which often result in injury.

INNOVATION IN NEW MATERIALS

The challenge with mechanical hand protection has been to provide workers with comfortable products, while meeting the ANSI/ISEA 105 cut protection ratings required for the occupational risk level. Recognizing this need, SW® Research & Development engineers explored new methods and materials to address this comfort and cut resistance challenge. The team eventually identified a proprietary yarn technology, which SW has branded as AxiFybr®, that enables hand protection with enhanced wearer comfort at higher cut and abrasion resistance levels.

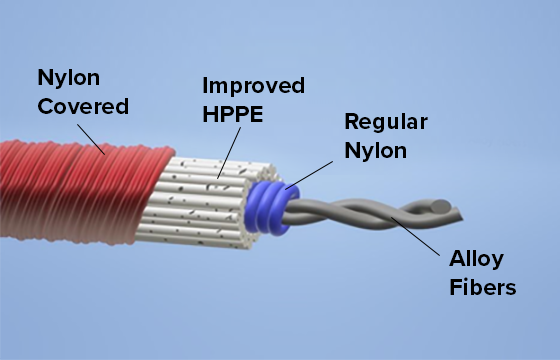

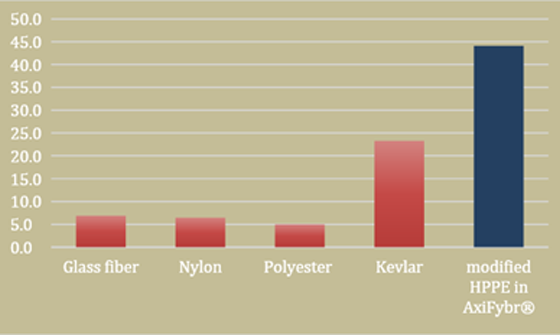

AxiFybr is a proprietary engineered yarn that consists of two types of strands woven together. The first strand of these cut-resistant yarns is the inner core, which is engineered with twisted metallic alloy fibers that are bound with regular nylon. This structure provides a higher level of cut resistance than other typically used core materials, such as fiberglass, steel, and basalt, while still providing comfort. The second strand, or outer wrap, of AxiFybr is constructed with a nylon-covered, modified high-performance polyethylene fiber (mHPPE), a synthetic material with a unique flecked crystalline structure that is 15 times stronger than conventional cut resistant yarns. Together, the inner core and outer wrap of this proprietary yarn delivers high cut and abrasion resistance, and greater tenacity (as measured by grams per denier, or g/den in the graph below). This results in a fiber strand that is 48% stronger than traditional cut-resistant fibers.

Chart 1: Liner knitting yarn type – Tenacity (g/den) |

|

COMFORT |

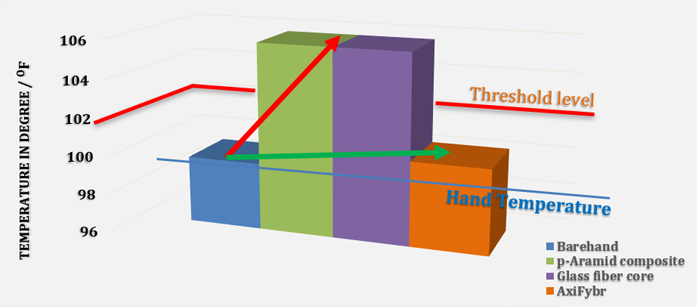

One of the main aspects of worker comfort is the glove’s breathability while maintaining structural integrity and cut protection. Commonly used glove materials like glass fiber, Kevlar, and polyester can be abrasive, non-porous, and even leave residue on the skin. Without proper fit and feel, wearing gloves for extended periods of time can lead to overheating, sweat, and ultimately discomfort. The mHPPE in AxiFybr, however, ensures that cut-protective gloves are not only high performing, but also moisture-wicking. This unique element provides the comfort and breathability required for demanding work while minimizing skin irritation due to sweat buildup and overheating. The longer lasting comfort of gloves made with AxiFybr ensures workers will wear the proper gloves at the proper times without having to compromise on their needs.

Chart 2: Temperature Change

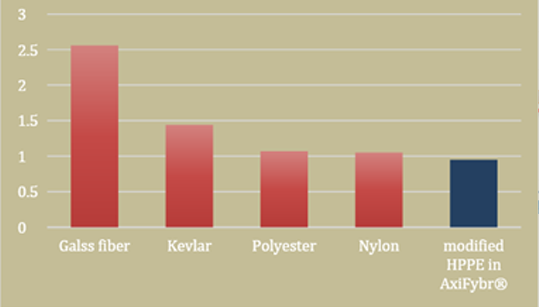

In addition to cut resistance and comfort, it is equally essential to consider the level of dexterity in mechanical protection. Cut-resistant gloves are generally made with materials like Kevlar and glass fiber, which tend to have higher material density (as measured by gram per cubic centimeter in the graph below). Though these materials provide significant mechanical protection, gloves made with these fibers tend to be stiffer and bulkier– leading to increased hand fatigue. The abrasive nature of these materials over prolonged periods of use cause pinching, discomfort, and roughness against the skin. However, the proprietary fiber combination in AxiFybr creates a dexterous glove that is lightweight and easy to maneuver in. As a result, gloves made with this engineered yarn dramatically reduce hand fatigue, stress, and irritation.

Chart 3: Liner knitting yarn types – Material Density (g/cm3) |

|

DURABILITY |

One of the disadvantages of typical fibers used in mechanical protective gloves is the loss of cut and abrasion protection over time. However, the knitted metallic alloy and mHPPE fibers present in AxiFybr products hold up in the most demanding environments, even with machinery use and in oily conditions. Studies have shown that gloves made with these engineered yarns are 21% more cut-resistant and 2x more abrasion resistant than gloves with traditional fibers. Unlike conventional fibers, AxiFybr can withstand frequent washing–even with alkaline based detergents. Its advanced technology ensures the structure, protection, and comfort of these gloves is preserved much longer than competitors.

CONCLUSION

A cut-protective material that delivers higher cut and abrasion resistance levels while maintaining comfort, dexterity and durability is long overdue. In its simplicity, AxiFybr addresses the range of common difficulties present in physically demanding work environments. From its proprietary composite blend, to its lightweight structure, to its long-lasting capabilities, this engineered yarn technology meets the most pressing needs in mechanical protection. With AxiFybr, workers don’t have to sacrifice comfort, dexterity, and durability for safety.

View our BULLSEYE and GraphEx line of cut protection gloves, featuring AxiFybr!